Laser powder bed fusion is a highly sensitive process. Understanding exactly what is going on throughout a build is critical for part repeatability.

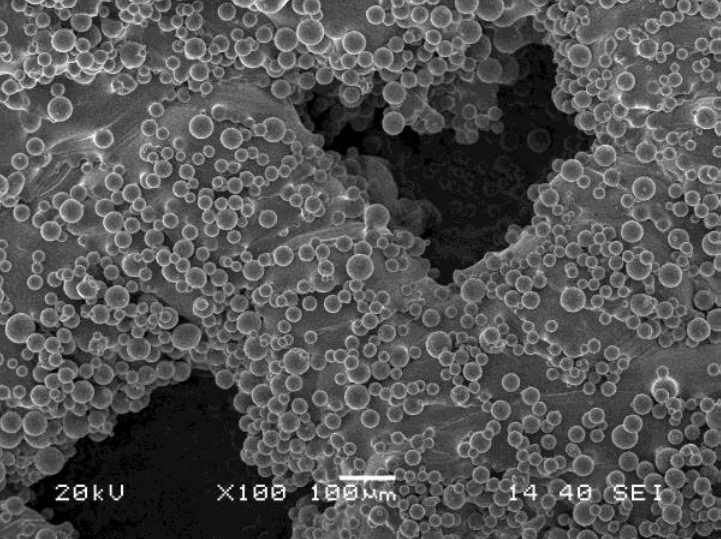

Scanning electron and optical microscopy inspection reveal all the details. This 100x view shows powder globules stickied to the part prior to media blasting.

Titanium is highly sensitive to oxygen. Too high or too little oxygen will cause the material to fall out of spec. We check oxygen levels with every build.

X-Ray EDS lets the customer know exactly what is in the metal. Our parts are silicone and aluminum oxide free.

Dimensional accuracy and consistency is critical. Metrology is the art of capturing those dimensions and analyzing them. Robust dimensional checks ensure proper fit and function.

Different phases of metal have different properties. We want to be sure the material is properly melted and free of brittle regions.

A look inside your part reveals any voids or unmelted regions. CT is an excellent way to inspect parts before going to final production.